The home of Specialist Crafts, supplying Irish classrooms for over 20 years ![]()

Checkout using your account

Checkout as a new customer

Creating an account has many benefits:

- See order and shipping status

- Track order history

- Check out faster

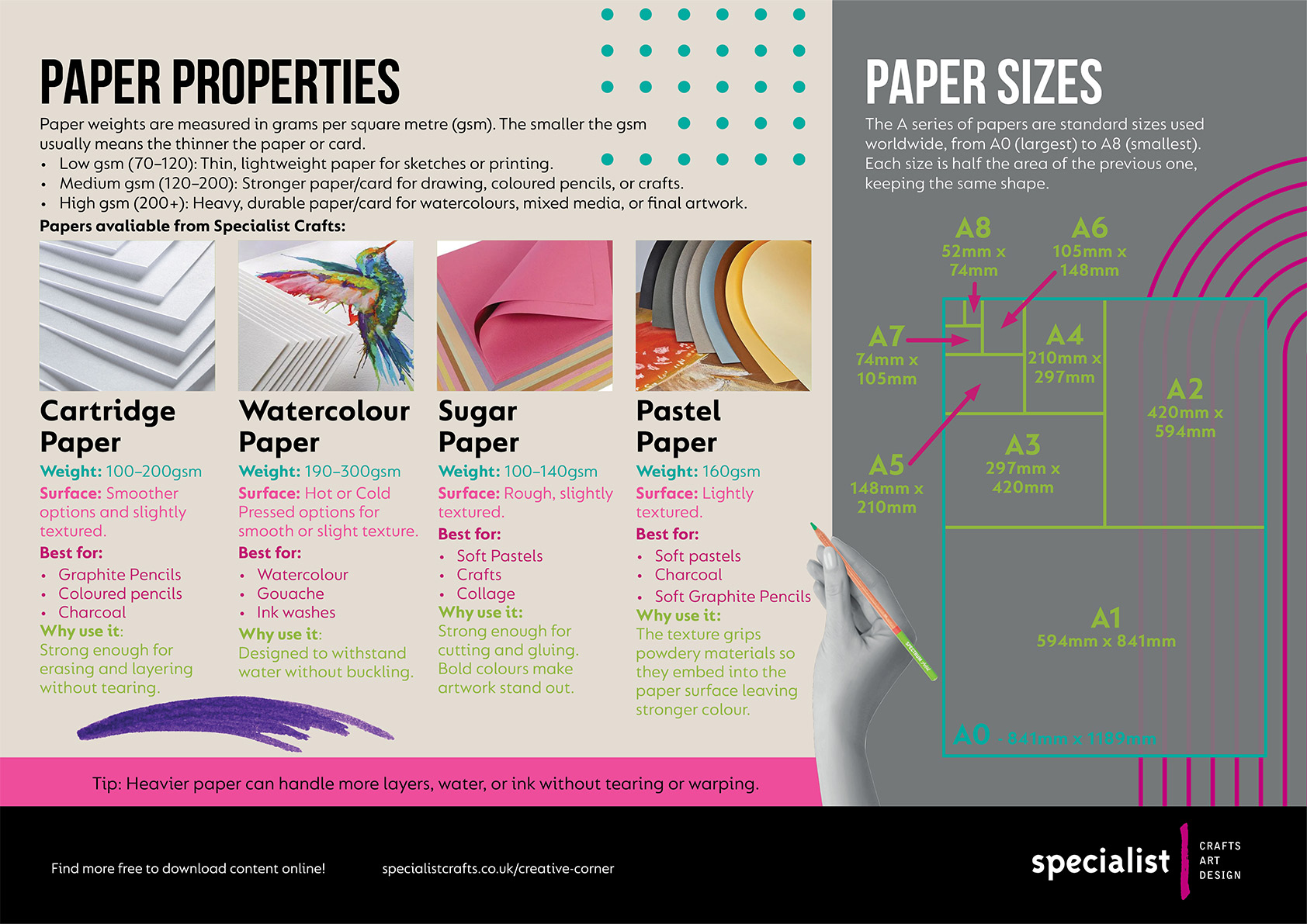

Make Your Own Paper - a complete guide

Make Your Own Paper - Introduction

You handle paper in all sorts of different forms every day. You probably know that it has been made on huge and complicated machinery, yet you can make it yourself by hand in your own kitchen, back yard or classroom, using waste paper as raw material. What’s more, you can do it successfully from the outset using only the simplest equipment.

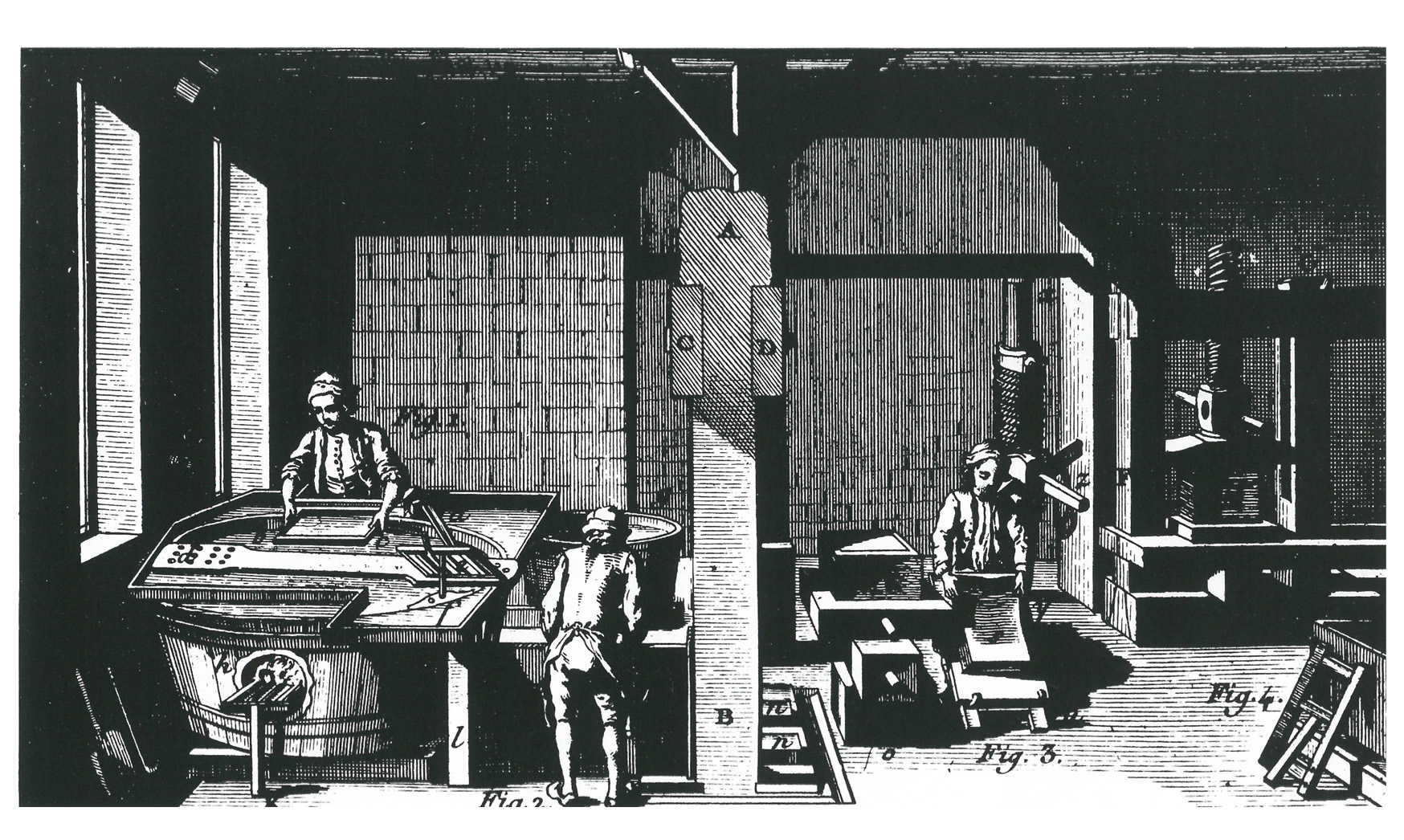

The process of papermaking is a very ancient one. Most authorities credit the invention to T’sai Lun, an imperial official in China in 105 AD, but possibly the first paper was made even earlier. In 751 the Arabs, besieged by the Chinese in Samarkand, captured one of the enemies and forced out of him the secret of paper making. By the 12th Century the art had spread to Spain and Italy through contact with the Arabs. At last, in the late 15th Century, it reached the British Isles.

T’sai Lun made his paper from the bark of trees, waste linen, old rags and fishing nets. The essential feature was that all these items were of vegetable matter, made up of fibres held together with a kind of natural glue. When the glue was washed out, only the fibres remained and when these were thoroughly beaten with sticks and then suspended in water, they formed a pulp. T’sai Lun dipped a fine screen into this pulp and when he withdrew it the screen retained the fibres and allowed the water to drain through. The fibres matted together and, once quite dry, made a sheet of paper. This is still the principle of paper making today, even on the huge machines of the largest manufacturers.

Contents

In Europe and the United States paper makers used linen and cotton rags for their raw material; nowadays paper is made mainly from pulped soft wood, though rag-paper is still used for certain purposes such as the making of bank notes, where great strength is needed to withstand rough handling. The machines now used for making paper are the direct descendants of the first machines developed by the Fourdrinier brothers and by John Dickinson in the early 19th Century. Paper continued to be made by hand until the present day, though now there are only two mills in England still making it.

The craftsmen who work in those mills are highly skilled and you will not be able to match the quality or quantity of their product but the method described in this book is based on the same principles as theirs. Waste paper is readily available and easy to use; the paper you make will look good and have a nice feel to it, but cannot equal rag-paper for strength

What You'll Need

Paper Pulp

Frame & Deckle

Vat or Cage Container

Couching Cloth

Aquapel Size (Optional)

Paper Making Press

Brusho Crystal Powder (Optional)

Embellishments (Optional)

Manchester Museum of Science & Technology

Essential Equipment:

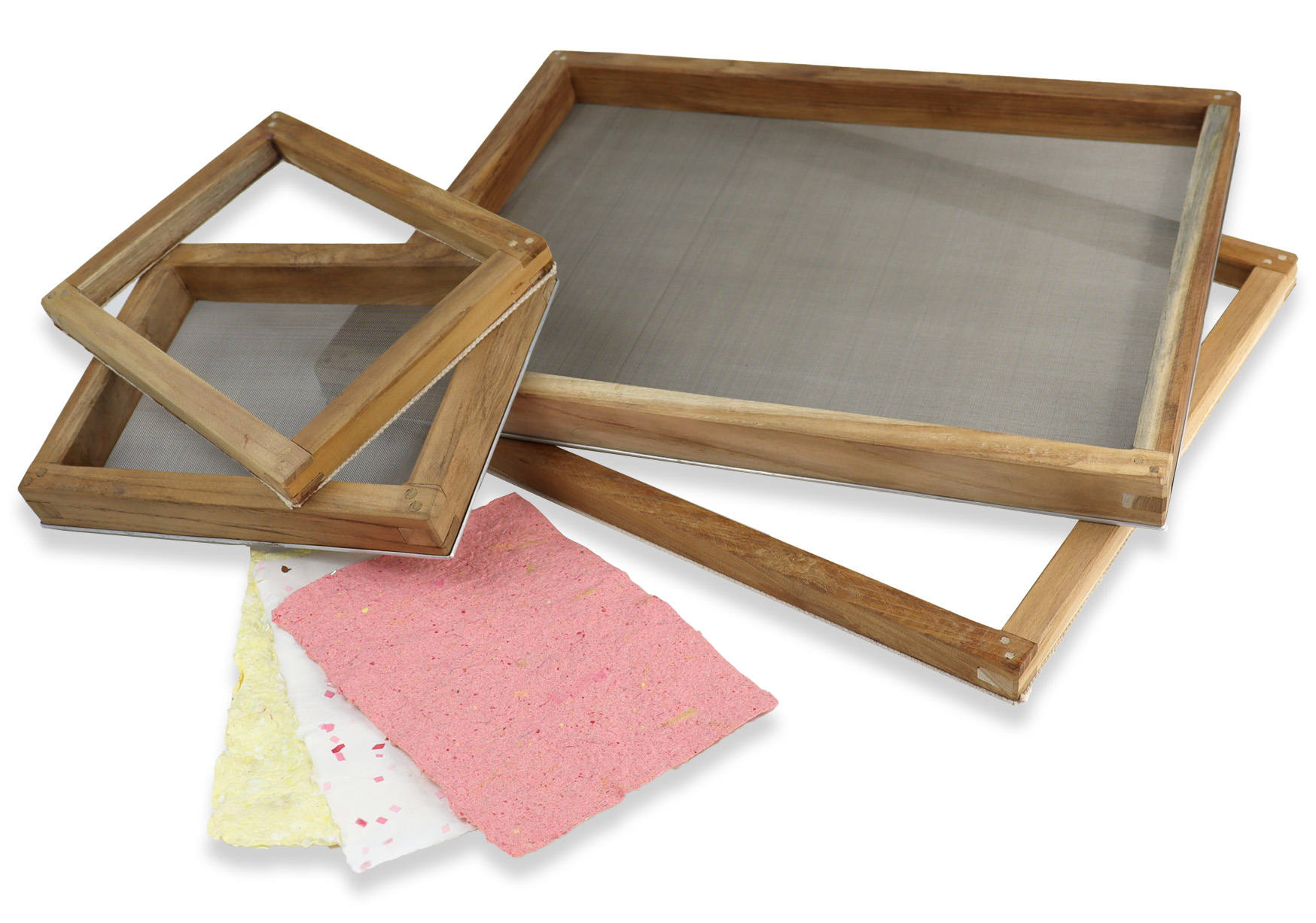

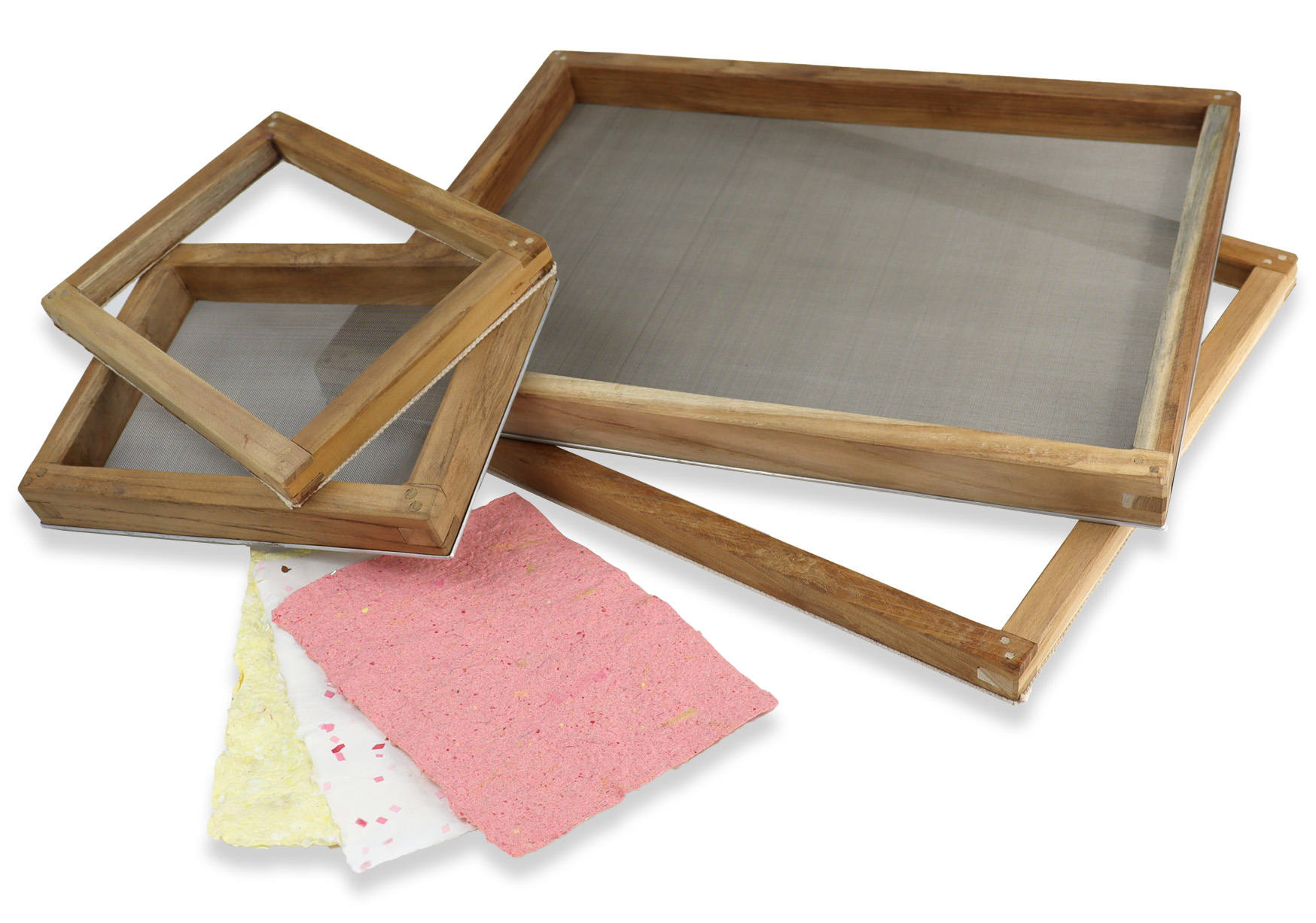

Frame and Deckle

If making your own, this is a frame made from ordinary planed softwood. Corners, which must be square, must be waterproof glued and pinned with oval nails. The completed frame should lie flat and be sandpapered to remove any sharp corners or edges. To make an A4 sheet of paper the internal dimensions should be 29.7cm x 21.0cm. Across the frame is a mesh, stretched as tightly as possible, which can be terylene net curtain material, coarse screen-printing nylon or perforated zinc. Ideally, the mesh should have about nine holes to the centimetre. The mesh can be glued, stapled or fixed with drawing pins to the frame of the mould, (see fig. 2). If drawing pins are used, they should be attached to the sides of the frame, not the face.

The deckle is another frame of identical dimensions to those of the frame, but without the mesh. It sits over the meshed frame to create the deckle edge of the paper.

Couching Felts

About thirty cloths are needed for supporting the pulp after moulding and during pressing. Mopping-up cloths are ideal. (Only use the very smooth variety of cloth as those with small holes and a texture surface will spoil the appearance of the paper you make.) Cut the cloths to 34cm x 25cm if making A4 sheets of paper.

Press

You need two thin boards (approx. 34cm x 25cm). The press is held together by four 1cm x 10cm bolts with wing nuts.

Vat (Optional)

A rectangular watertight bath with a capacity of about 28 litres and internal measurements 54cm x 34cm x 17cm deep. This is listed as ‘optional’ because an ordinary sink will do quite well, although you may have to reduce all proportions given in this book if the capacity is under 28 litres.

Liquidiser (Optional)

A kitchen liquidiser makes quick work of the first stage of pulping the raw material, but beating, pestle and mortar fashion in a bucket with a stout piece of wood will get the same result rather more slowly.

Aquapel Size

Add to paper pulp during the pulping process to produce a much stronger paper that is resistant to water-based colour mediums. Mixture should be approximately 98% water and 2% Aquapel.

Raw Materials:

Paper makers call their raw material the ‘furnish’. In theory you can use any kind of waste paper for your furnish but newspapers are good because they are readily available in quantity and they break down easily. Pink newspaper combines well with the black ink and makes a gentle shade of brown. Colour printed magazines should be avoided, as some coloured inks may contain toxic materials. Photo copying paper of the dry variety also breaks down well and makes a very white end - product.

White paper, lightly printed, gives a good quality finish and brown kraft wrapping paper and old manila envelopes can be added to give extra strength.

You will need 150g for a batch, which is about 30 pages (15 sheets) of a full-size newspaper or double that number of pages for a tabloid. You must soak the waste paper first for several hours. If you can also boil it for an hour with a little detergent it will break down more easily and end up lighter in colour.

Pulping:

This is the process of breaking down the raw material into its basic fibres and mixing it with water. You can use a liquidiser or pulp the raw material by hand using a pestle and mortar. You can substitute a bucket and a stout piece of wood for the pestle and mortar. Take a handful of furnish, still wet from its soaking, put it into the mortar and beat it with the pestle until there appear to be no more recognisable pieces of newspaper. You can test this pulp to make sure it is well broken down by putting a little in a jam jar and shaking it up with waste. Any lumps remaining in the furnish will show up in the jar.

When you are satisfied with the first handful, put it into a bucket and repeat the process with a second handful, continuing until all the furnish has been pulped.

Because a domestic liquidiser turns at about 28,000 revolutions per minute it is obviously going to break down the furnish more quickly. The 150g of furnish will be about eight charges of a 1 litre capacity liquidiser, so divide the wet furnish into eight equal sized lumps. Put the lumps into the liquidiser, fill up with cold water and run the liquidiser in short bursts. A liquidiser should not, of course, be run continuously. About a minute of short bursts is enough to break down the furnish. Use a bucket to hold the pulp you have made.

When pulping is finished you will have about eight litres of pulp at a consistency of 2% fibre and 98% water. Pour just over half the pulp into the vat and add 17-18 litres of warm water. The pulp has now been further thinned down to less than 1/2% fibre. The rest of the pulp is kept in its bucket to be used for topping up the vat since each sheet of paper you make will reduce the strength of the pulp.

If using a kitchen sink for the vat, put in only three litres of pulp and fill with warm water.

After a gentle stir, you are ready to make the first sheet of paper. Place the deckle on top of the mesh covered side of the mould and hold the two firmly together with one hand on each of the short sides, thumbs on the deckle and fingers under the mould, (See below). Stand at the vat or sink, holding the mould and deckle vertically over the vat. Dip the bottom edge into the vat at the far side of the vat and, once it is below the surface of the pulp, level the mould so that it and the deckle are just covered by pulp.

Let the mould and deckle rest for a moment in the pulp and then steadily but swiftly withdraw them. There will be a layer of pulp on the mould, its edges contained by the deckle.

Shake the mould slightly from side to side and forward and back to help the fibres to mesh together. After a few seconds there will be some surplus water lying on the surface of the mould, if you pause to let this drain through the mesh you will get a thicker sheet of paper; if you spill it over the edge of the deckle the paper will be rather thinner. Practice will tell you how to achieve the thickness of paper, which suits you best.

Couching:

Couching is the name traditionally given to the next operation. The pulp must be transferred from the mould to a cloth which can hold it until it has been given enough strength by pressing to support itself.

Take one of the thin pressboards and lay on it two couching felts, one on top of the other. You can place the press board on two blocks of wood, standing in a drip tray, if you want to avoid spilling the water which will drip from the sheets you are going to stack up on top of each other.

Take the deckle off the mould and lay it to one side. Holding the frame in both hands turn it over so that the pulp is underneath and press it onto the couching felt, starting with the long edge furthest from you and continuing with gentle pressure until all of the pulp is on the couching felt.

Grip the mould and the pressboard tightly together, with the pulp trapped in between, and tilt them so that any water which has oozed through to the surface of the mesh can be poured off.

Lay down the mould and pressboard once more and slowly lift off the mould, starting with the near edge. If the pulp shows any tendency to remain attached to the mould at the edges, run a finger round the edges of the mesh to free it. One of the pleasures of paper making by hand is that you will only really know how the job has turned out when it has had time to dry. Often an apparent disaster turns out to be a success!

In laying down the couching felt you must take care to avoid wrinkles. The making of a stack of paper, called a post, continues with alternate layers of pulp and couching felt. From time to time give a gentle pressure in the centre of the mesh before pulling off a new sheet in order to expel any air trapped under the sheet.

The quantities of furnish and water recommended will make anything from 16 to 28 sheets, depending on the thickness you allow. The thickness will depend both on how long the mould remains in the pulp and on how much loose pulp you spill off after withdrawing the mould from the vat.

The mixture remaining in the vat can safely be poured down the drain as it is too thin to cause a blockage.

Pressing:

When you have made the last sheet, cover it with one last couching felt. The post, which can be made of as many sheets as you wish to make is now ready for pressing. Place it between the paper press and tighten the bolts a little at a time on each in turn so that an even pressure is maintained. Go on until you can tighten no further. Finally, stand the press on one edge so that the water which is squeezed out drains away and leave it for 15-30 minutes.

After this time, undo the nuts and remove the boards and felt at the top of the post to expose the top layer of paper. It has now reached its final thickness and really looks like a sheet of paper, but it will still be very damp and must be handled carefully. Peel it, still on its own couching felt, and lay it on a flat surface or a spare board to dry. Repeat this process with all the other sheets you have made and leave them to dry.

How long drying will take depends on a variety of factors - wet or dry weather, cold or warm, indoors or outside. After a couple of hours, separate the sheets from their couching felts using great care as they are still damp and delicate. The easiest way is to lay each sheet in turn face down on a flat surface and peel back the couching felt from one end.

Do not leave this stage too late; once the sheets have begun to dry all over it will be harder to part them from the couching felts.

Allow the separated sheets to dry for a further 2 - 4 hours and then lay them one on top of the other between two boards. Place this stack under a light weight, such as two or three books. This helps to correct any unevenness in drying and they can be left like this for twelve to twenty-four hours.

After that, they should be laid out, singly or in pairs, for further air-drying. Once they seem quite dry the sheets can be stacked and put under a heavy weight for two or three days. Ten books should be heavy enough for this purpose.

If you are impatient to see how the work has turned out, you can condense this drying process into a few hours or even less by using heat from a radiator or electric fire to speed up drying, but you may get curled edges to your paper.

The vat, frame and all your buckets should be washed out well after each batch, because old, dried pulp will spoil the appearance of the next making. The couching felts need to be washed out occasionally. Pulp can be prepared before you need it but it should not be kept for more than two or three days as it eventually gets rotten and begins to smell.

Apperance:

The paper you have made will have rough edges because a little of the pulp will have flowed under the deckle during framing. This effect is called a ‘deckle- edge’. It used to be insisted upon for high quality writing paper, indeed some machine-made paper was deliberately made with a deckle edge to satisfy this demand. If you don’t care for it, you can guillotine your paper to give a straight edge or cut it with a sharp knife and ruler.

The surface of the paper will be rather rough; this too is part of the charm but if you prefer a smoother surface, you can roll the sheets with a rolling pin or smooth them with a warm iron.

Sizing:

Not adding size to your paper will make your paper not as strong. It is fine for typing on or for writing on with a pencil or ball point pen, but fountain pen ink and water colour paint will tend to run a little. This may not be a bad thing; the effect was prized by artists in ancient China and works very well with a modern felt tipped pen.

The paper can be sized to make it stronger and more resistant to water-based colours by adding chemicals to the pulp in the vat during the pulping process, such as Aquapel Size.

The alternative is to ‘tub-size’ your paper, which means to dip it in a bath of size after it has been made and dried, although it is much easier to add during the stage mentioned above.

Adding Colour and Texture:

The dispersion of ink from the original paper throughout the pulp will make your paper grey. Boiling the waste paper in detergent will lighten it and adding Brusho Crystal Powder to the pulp will change the appearance of your paper. You won’t need to add much of this, as the powders are highly pigmented. White waste paper with not too much printing on it will give an almost white paper. You can also use coloured paper such as pink newspaper as stated previously. You can also experiment adding food dyes during the pulping stage, or laying your paper in a bath of diluted food colouring after it has been made.

Scatter leaves, skeleton leaves and other embellishments on top of your wet pulp after dipping the frame and deckle under, the petals will become part of the paper adding extra colour and textures.

Marbling:

Handmade papers, whatever colour they may be are ideal for marbling. They may be used both sized and unsized, although the effects will vary slightly with each. Subtle tones and colours - particularly if used on a pre coloured paper, and strong, deep colours obtained with oil-based printing inks.

Paper often has a watermark, which can be seen when the paper is held up to the light. The effect is obtained by blocking up some of the holes in the mould mesh. Where the holes are blocked, the paper becomes thinner. You can make your own watermark by drawing a design on the mesh of your mould and then filling in the design with any glue which becomes waterproof when dry. You can also reproduce the design by weaving thread through the holes of the mesh. The design must be kept very simple if it is to be recognisable.

Uses for Your Paper:

Letters written on your handmade paper are going to have a unique quality but there are many other uses for the paper. It can be printed, (letterpress printing is best), to make business cards, greeting cards and postcards. You can make it up into scrapbooks and memo pads.

It can be glued and glazed with PVA adhesive to make folders and small boxes. Single sheets can be laminated together with adhesive to make thick boards and these boards can be used as covers for books.

It may be printed using linocuts and other block printing materials, which on a coloured handmade paper, add an exciting quality not produced on smooth, machine-made paper. For these processes, it may be necessary to slightly dampen the paper first.